What is the Difference Between Full Bore and Reduce Bore Ball Valves. Full port vs redcue port ?

Last month, I was asked by a customer what is a full bore ball valve? I think this is a great idea to share with readers.

In citations use valves or valve related documents when designing the system. People will give information about the valve, especially the ball valve. Machinery chains for the oil and gas industry or anywhere else. When you hear about a full bore ball valve or a reduce bore. Then surely they are talking about different types of ball valves.

There are two terms full bore and full port, both are exactly the same. The only difference is that full port is a term used a lot in the oil and gas industry. Or also the terms reduced bore and reduced port, both are the same. And are understood to be the same.

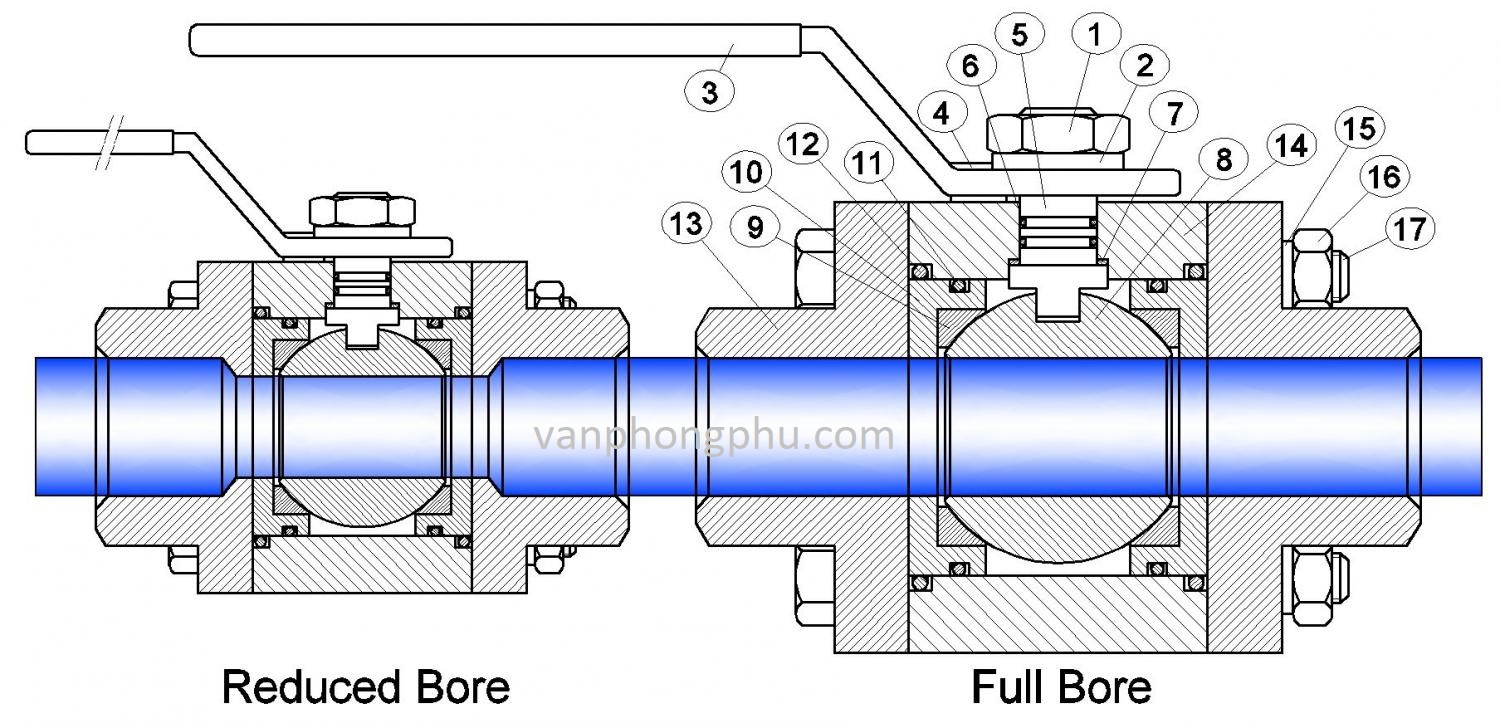

Looking at the comparison image below, we see that:

– Full port ball valve (full bore): is a valve with the diameter of the ball hole coincident with the diameter of the pipeline. Thus, the medium that passes through the full port ball valve will not be affected in terms of flow and pressure. The price of full bore valve is higher than reduce bore.

– Reduce port ball valve (reduce bore): is a valve with a ball hole diameter smaller than the diameter of the conduit. Thus, the medium that passes through the reduce port ball valve will be reduced in flow and pressure. The price of reduce bore valve is cheaper than full bore.

What is a angle seat valve? What is a pneumatic angle seat valve? What is an angle valve used for? How does angle valve work?

1- What is a angle seat valve?

Angle seat valve is a valve belonging to a globe valve with a tilt structure that opens and closes by the piston and adopts a crank or pneumatic actuator, like other valves, it is also used a lot in industry. especially the steam and water industries.

The angle seat valve has a low level of resistance to water flow and is less affected by water hammers compared to other valves

2- Classification of angle seat valve

We can classify the oblique valve according to two main types, of which the pneumatic slant valve is more commonly used. In addition, these can also be classified according to the normally-closed and the normally-open.

– Hand wheel angle seat valve

– Pneumatic angle seat valve

3- Structure of angle seat valve

The valve structure is quite simple and is divided into 3 main parts for easy understanding, including:

– Body: stainless steel, copper, steel …

– Piston

– Actuator: Hand wheel or pneumatic

4- Working principle of the angle seat valve

The valve operates open and closed by the piston through a hand wheel or pneumatic control mechanism. With a crank like a globe valve, when rotating in the direction of opening the symbol, the piston lifts and the solvent passes, while when the piston is back, the piston closes and the flow is interrupted.

For pneumatic control, the air pressure entering the actuation valve chamber pushes the piston moving so that the valve opens, while the valve is stopped when the supply is stopped. Note that the same principle applies to normally open valves.

5- Price of pneumatic angle seat valve

Pneumatic angle seat valve is also used quite popular, its price is also very competitive and attractive as the control ball valve. But compared to the ball valve, it is used a lot less, but the quality is not inferior to the control ball valve.

This article is edited by engineers Huu Manh – V2P. Please respect the copyright by including the original link when you copy content from here. Thanks

The difference between globe valve and gate valve

Before we can compare globe valves and gate valves, we need to understand what is a globe valve? What is a gate valve?

Globe valves and gate valves are the two types of valves used in many pipelines, they have many similarities in materials and appearance, sometimes people confuse the two types because of the shape. quite similar of some gate valve lines with globe valves. We would like to point out the differences so that readers can easily distinguish.

Fig1: Gate valve

Fig 2: Globe valve

1- valve structure

– Globe valve: has a horizontal valve disc structure, a saddle-shaped body or a falling letter, so it is also known as a falling valve

– Gate valve: valve disc structure is a form of vertical wedges such as a door or gate, the opening and closing will be faster than the globe valve.

2- Function used

– The outer valve is used to close – open the fluid, it also has the effect of regulating the solvent in the pipe as you like.

– Gate valve – gate valve is only used to open and close the medium only, if used to regulate the medium will not stand and will damage the valve disc. Gate valves are usually installed at the upstream, and globe valves are often installed at the end of the pipe.

3- The flow of the medium

– Globe valves have a fluid flow in a certain direction and are clearly specified on the valve body. It has 3-5 times more flow resistance than gate valve.

– Gate valves – gate valves flow in both directions without necessarily having to be set in either direction. In addition, it has a very low flow resistance coefficient from 0.08 – 0.12

4- Cost

What we are interested in is the price of the two valves. Globe valves are always priced higher than gate valves, gate valves are the second cheapest after the butterfly valve.

What is a Solenoid valve? What is a solenoid and what is it used for? Where are solenoid valves used? What are three types of solenoids? What is an example of a solenoid?

The solenoid valve is a valve that opens and closes thanks to the action of an electric current. It is also known as an automatic valve … The purpose of the valve is to control the refrigerant in the pipeline through supply control, which can be considered as an automatic and applied valve. much about automatic solvent control work.

1- Structure of solenoid valve

There are many types of solenoid valves, but the general structure of the solenoid valve consists of 4 parts

– Valve body

– Valve disc (some types are diaphragm)

– Springs

– Electric coils

2- Classification of solenoid valves

They are divided into several categories according to the structure, material, application as we use and call

– Structure: 2-way solenoid valve, 3-way solenoid, flange solenoid valve, threaded solenoid valve …

– Materials: stainless steel solenoid valve, copper solenoid valve …

– Medium: pneumatic solenoid valve, steam solenoid valve, water solenoid valve …

– Voltage: 24V solenoid valve, 220v solenoid valve …

But actually such a division is inaccurate and inaccurate about the nature of the valve. The solenoid valve is actually an automatic valve to control the solvent so that it can only be classified into two categories as follows:

– Normally closed solenoid valve

– Normally open solenoid valve

3- Applications of the solenoid valves

As mentioned above, the solenoid valve nature is a type of automatic valve counting the control of the solvent in the pipeline so that it is applied practically in daily life and in industries.

– Life: application for automatic watering systems for plants, automatic water supply systems …

– Industry: used for gasoline, gas, compressed air, water, steam. For petroleum, fertilizer, sewage treatment, food and pharmaceutical, beverage factories …

Distributor of AZ armaturen valves in Vietnam

V2P is the official distributor of AZ products in Vietnam. We are proud to be a professional distributor chosen by large manufacturers as distributors in Vietnam.

AZ Armature is a specialized valve manufacturer in Germany, with factories in many countries: Germany, Brazil, China … AZ’s valve products serve the industries: Chemicals, oil refining, houses paper machines, thermal and hydroelectric plants, mining, steel industry …

Lining valve products such as: ball valve, liner valve … serve many factories, need stability and durability. The chemical leakage into the environment is particularly serious, which affects greatly production. Therefore, the use of AZ valves is a wise choice.

Specialized valve products for acids: HCL, H2SO4, HF, HNO3, H3PO4 with concentration up to 99% of AZ which are famous in the world. Top quality and excellent chemical resistance have made a name for itself in the specialized valve industry.

Pls contact: Mr Phong +84936 662 69O (Vietnam)/ Mail: phong@vanphongphu.com

Sometimes we wonder: What is ductile iron? What is cast iron? What is white cast iron? What is gray cast iron Difference between Ductile cast iron and cast iron – Gray cast iron

So let’s find out what is cast iron?

Cast iron is an alloy of iron and carbon with a content greater than 2.14%, plus silicon. Cast iron was used by the Chinese as early as the 4th century BC, until the 14th century when Europeans used it.

Classification of cast iron:

Cast iron is classified into several categories, but only the main categories are as follows

1- Cast iron

2- Ductile iron

3- Gray cast iron

4- White cast iron

Sometimes you hear your partner ask you about gangs in general they’re talking about gray cast iron, why is that?

Gray cast iron is simply the cheapest of the above and it is also the most commonly used.

What is the difference between Ductile cast iron and cast iron?

Ductile iron is a kind of ductile iron, malleable, not broken while ductile iron is easily broken. Its composition includes: iron, carbon, silicon, manganese, magnesium, phosphorus … Due to its high ductility, ductile iron is widely used in the automotive industry, plumbing … While Cast Iron is widely used in construction industry.

In 1943, Keith Millis was the first to register the Ductile Cast Iron copyright with the US state. Other documents say ductile iron has been found long ago by others.

Cast iron in valve industry:

In the valve industry, cast iron is used heavily and mainly for hot air valves because of its heat resistance, the commonly used types are: Ductile iron and cast iron.

Ceramic lined valves for inorganic and organic chemicals

As we know, in many industries today the use of chemicals to serve the daily production process, the use of chemicals can be in the form of solids or liquids, it is contained in the basin and piping leading to the site of use. To ensure safety and avoid risks, storage tanks and pipelines must also be made of materials resistant to chemical environments.

Chemical resistant valves are installed on pipelines with the opening and closing effect, controlling the flow of chemicals to ensure the proportion of chemicals used as prescribed. In the past, people often made valves with chemical resistant materials, but after a while, the valves were also damaged, so the process of using chemical resistant plastic lining valves was born. It greatly improves valve life and maintenance time. But the disadvantage of Teflon, PTFE or PFA and PO plastic lining valves is that it is resistant to certain chemicals, so it is difficult in terms of solvent diversity. In recent years, ceramic valve lining technology has been born, with Alumina ceramic from 95%, 99% and 99.5%, bringing great requirements for chemical resistance.

With ceramic valve Alumina 99.5% or more resistant to most inorganic and organic chemicals, corrosive acids with high concentrations or alkaline chemicals: HCL, H2SO4, H3PO4, HNO3, HF, NaOH …

Why use V2P ceramic valve for chemical environment?

1- Inert with chemicals: With Alumina ceramic valve 99.5% or more or with Silicon Carbide almost inert with all inorganic or organic chemicals. It does not interact as well as is physically and chemically stable, resisting most acids and alkalis.

2- Abrasion: Ceramic lining valve (ceramic) has 750% harder than stainless steel, 43% harder than zirconia, 140% harder than normal porcelain.

3- Durable: Even when soaked in chemicals for a long time, the ceramic lining valve is not affected, it gives long-term use.

4- Warranty up to 12 months.

Different ceramic lining materials for different applications:

1- Alumina (Al2O3) is the most economical ceramic lining material but has high corrosion and abrasion properties

2- Zirconium (ZrO2) for high durability but only withstand temperatures up to 320 degrees Celsius

3- Silicon Nitride is used for high temperature resistant applications, maximum temperature is 950 degrees Celsius

4- Silicon Carbide (SiC) For highest hardness in the group of ceramic materials but very low breaking strength, so it is easy to break. It is inert with most chemicals, especially HF acid.

In life sometimes we come across copper types with names such as: copper, brass or gray copper without understanding their nature of what it is, how it is, why it is called that way. So learn to distinguish between copper and copper?

What is copper?

Copper is a flexible metal with high electrical and thermal conductivity, symbolized Cu and melting at 1,085 degrees Celsius.

Copper

Copper is a pure red copper. Copper is used for many products because of its high electrical conductivity, corrosion resistance, good formatting ability … Pipe fittings, industrial valves, electrical cables all use copper, copper is easy to use. welding and polishing. In addition, copper is also resistant to bacteria and can 99.99% of bacteria after more than 2 hours of exposure.

Brass

Brass is an alloy between copper and zinc, it is light yellow and looks like gold. Depending on the proportion of zinc in the mixture, it varies in color, ductility and durability.

If the zinc content is from 32% – 39%, it will increase heat resistance but limit cold tolerance

If the zinc content is> 39%, it has increased strength and reduced ductility

Brass has many applications in decoration, musical instruments and in industry.

Bronze

An alloy of copper with nickel, phosphorus, aluminum, manganese, silicon. All of these components make a alloy harder than pure copper. This copper has a characteristic dull gold color, it is used for sculpture, musical instruments, and in industrial applications.

A Gate valve (stop valve) is an opening and closing valve by lifting and lowering a gate. Gate valves require less space along the pipe axis and hardly affect the flow of media in the pipe.

Structure of gate valve: crank, valve body, gate valve, gasket, connecting shaft, valve cover

How the gate valve works:

Gate valve closes when performing manual rotation clockwise to lower the gate. The valve opens when turning counterclockwise to lift the gate.

Check out the video below:

Application of gate valve:

Gate valves are cheaper than other collapsible valves so it is widely used and popular, in addition because it does not affect the flow of the medium in the pipeline so it is commonly used in water sector.

Gate valve classification:

In Vietnam, depending on each person, people can call gate valves according to different types such as copper gate valve, stainless steel gate valve, flanged gate valve, cast iron gate valve, cast iron valve, submersible valve company, steel gate valve … But actually divided valve is only divided into 2 main categories:

1- Gate valve – valve of submerged valve: is the valve with submerged valve of the crank, when making and opening the valve, the valve will not protrude. As such, it is difficult to know whether the valve is closed or opened.

2- Gate valve – Floating gate valve: is a valve with a float higher than the crank, when closing or opening the valve will be higher or lower than the crank, so it is easy to know whether the valve is closed or open.

Check valves are used a lot in life, sometimes we see many types of check valves that do not fully understand them. Today we would like to summarize and summarize the 1-way valve:

Definition A check valve is a type of valve that allows the solvent to pass through without being returned (like it is a one-way street).

What it does: A check valve protects the pipe from a drop in front of the valve, that is, when the fluid in the pipe in front of the valve drops, the fluid behind the valve will not flow back to where it was pushed. One-way mounting also protects the pipe from breakage caused by pressure drop. In addition, it also has flow direction separator.

Application: Check valve used for water, gas, oil, compressed air, steam …

Principle of operation: The non-return valve operates thanks to the pressure difference before and after the valve. The valve opens when the pressure before the valve is greater than the pressure of the valve’s default spring, the valve closes when the pressure before the valve is less than the pressure of the spring.

1- Swing check valve

2- Lift check valve

3- Wafer type check valve

4- Ball check valve

Since the 18th century, butterfly valves were used, which were also used by James Watt for steam engines at the time, which are now widely used for their advantages of being compact and cheaper than their counterparts. Others. other valve. Especially replacing ball valves in industries: oil, gas … There are many types of butterfly valves that can withstand temperatures up to 300 degrees Celsius and are used for the chemical industry.

A butterfly valve is an open and closed valve with the valve disc located at the center of the valve with a guide. Positioning bar connected to outside with handle open and close.

Principle of operation of the butterfly valve:

The butterfly valve operates with the principle of a closed valve disc. The valve disc opens and closes thanks to the external rotation of the handle via the connecting shaft between the control arm and the disc.

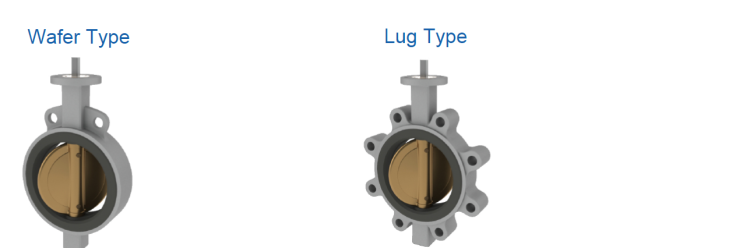

Butterfly valve classification: Butterfly valve is divided into 2 main types according to how it works

1- Lug type butterfly valve: This type uses multiple threaded holes (similar to 3-piece ball valves) that can be removed without affecting the other side. This is done by adding multiple threaded holes and two separate sets of screws on both sides of the flange.

2- Safety type butterfly valve: One type is used as check valve to prevent backflow of media

In the petroleum industry, long-distance transmission requires the use of booster pumps to propel the material to a long distance in the main pipeline. When dividing pipes into branches at facilities, it is imperative to use pressure-relief valves to reduce the pressure of the medium to a certain level with the purpose of protecting pipelines and conveying equipment. last.

Improper selection and use of a fuel pressure regulator valve may damage the rear units and cause fluid leakage. For example, with each drop of diameter 0.4mm / s, in 1 year we lose up to 200L. So to see the importance of the pressure valve.

With experience, we often advise customers to use gasoline – diesel pressure regulating valves from highly reliable manufacturers from industrialized countries G7 or EU. Gasoline-diesel pressure regulating valves are specially designed for use because the solvents have a higher viscosity index than water, compressed air, heat …

We recommend that you use: Yoshitake GD-200, GD-200H pressure regulating valve for reducing gasoline – diesel oil pressure.

Pressure regulator GD-200, GD-200H:

– Inlet pressure up to: 1.0MPa (GD-200) and 2.0MPa with GD-200H

– Use temperature: 5 -80 degrees Celsius

– Gray cast iron body, connecting Jis10K, Jis20K flanges

– Size: 15A -150A

– Used for gasoline, diesel and chemicals with viscosity below 600 cSt

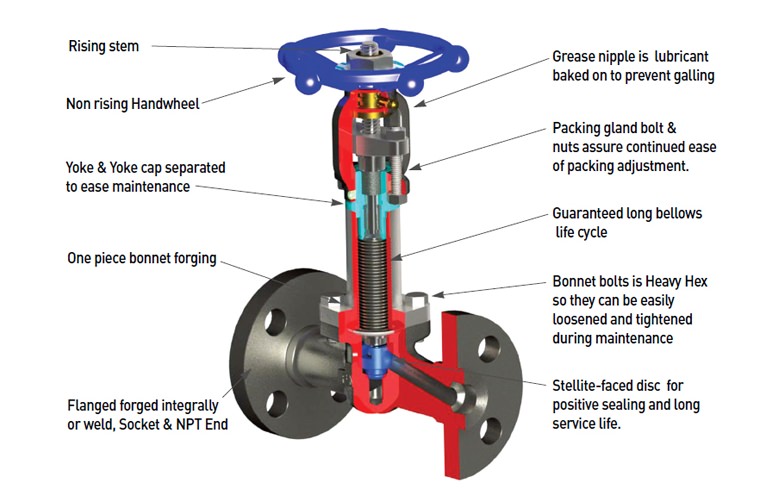

What is a Globe valve? What is a Bellows Seal Valve ?

1- What is a globe valve?

Globe valves are valves used to regulate fluid in a pipeline. It is named after the shape of the valve. Globe valve is also known as: globe valve, tipping valve, saddle valve, or in English it is called Globe valve, bellows seal valve.

Please refer to the principle of operation of the globe valve through the following video:

Normally, globe valves have only one sealing layer: lead gland packaging with lead or other materials. For industries like heat or chemicals, only one seal layer often causes leakage and chemical leakage. Leaking chemicals that are toxic or affecting operators and the environment.

Example: Like leaking a small drop of 0.4mm in diameter, it will cause a loss of 200L in a year.

2- What is a Bellows seal valve

Bellows seal globe valve: is a valve line of globe valves with the name of the seal class. The bellows sealing layer is an extended box-type seal, the bellows sealing layer is usually placed on the gland packing layer to seal the second layer to ensure to avoid valve leakage.

Recovery of condensate water for boilers, boilers, steam systems. Condensate recovery system

What is condensate?

Condensate is the steam which loses heat during transportation in pipes or after heat exchange.

Purpose of recovery of condensate for boilers:

Make use of heat

Reduce the amount of furnace discharge

Reduce the amount of added water

Thereby reducing the amount of fuel burned, reducing chemicals, reducing operating costs, maximizing boiler efficiency …

In fact, we often advise our customers on condensate recovery pump systems – mechanical condensate recovery stations for boilers for the many benefits it offers, including:

No power consumption

Long service life

No fire, explosion

The recovery time is from 4 to 16 months depending on the steam capacity you use. Of course the initial investment will be higher than the electric pump but in the long run you will find it much more efficient.

We have consulted and installed for many customers the systems – pump stations to recover condensate for the boiler by mechanical pumps.

Please contact us for Condensate recovery system: O936 662 69O (Vietnam)

What is a steam trap? What is a float trap? What is a bucket steam trap? Thermodynamic steam trap – Thermostatic steam trap? What are the types of steam traps. How is it work? How do I choose a steam trap?

1- What is a steam trap?

Steam strap a trap used for steam lines used to take condensate and retain steam (Condensate water is a steam that loses heat due to passage through pipes or heat exchange).

In fact, steam traps are also known with other names such as: discharge toads, condenser toads, toads, steam condenser cups, float cups, toads to drain condensate water, condensate draining devices …

Steam trap symbol in the technical drawing

2- Types of team trap

Steam strap is divided into 3 types

1- Float steam strap and Inverted bucket steam trap: The above two types of steam traps operate on the principle of density difference between condensate water and steam. The trap opens and drains the water when the water condenses into the lift chamber. The trap closes when the chamber is filled with vapor.

Advantages: Detects condensate and discharges in case of condensate, the discharge rate is greater than coin steam trap

Disadvantage: The price is higher than Thermodynamic steam trap, with the buoyant steam trap which is easily irritated. For bucket steam traps, it is easy to block the vents and air on the bucket.

2- Thermodynamic steam trap

A kind of trap opened and closed by a circular coin inside. This type of steam trap works by a combination of heat and thermodynamic motion.

The trap closes when: The condensate discharges at high velocity creating a low pressure zone below the coin (Bernoulli Effect) relative to above the coin.

The trap opens when the expanding steam loses its heat and becomes condensate

Thermodynamic steam trap is widely used in Vietnam because it is cheaper than other steam traps, but it also has the disadvantage of not recognizing condensation and can lose steam and retain condensate due to the use of traps. slightly poor quality money.

3- Thermostatic steam trap:

This type is rarely used and is not popular in Vietnam

Operation Principle:

– Equal to the temperature difference between the evaporator and the chilled condenser water.

– Equal to the difference in the thermal expansion of two metal layers.

– The metal plates are designed with many sides with different lengths to make the trap work at different vapor pressures.

– The trap opens and rinses when the condenser water cools below the temperature of the vaporizer and the metal piece returns to its flat position.

– The trap closes when the condenser water reaches the evaporation temperature and the 2 pieces of metal curl up and lift to close the valve.

– Drain trap stops continuously.

In the process of selling and consulting valves for the system that we have implemented, we often encounter problems of pressure reducing valves – pressure valves are often broken, leaking, and disc failure. Occurs in plants that use heat, compress air. Pressure reducing valves in Vietnam

Through observation and physical inspection, we find that the majority of problems that cause these errors have two main causes. We will analyze more closely to show you:

1- Using low-quality pressure reducing valve: To save costs, many customers using low-quality pressure reducing valves from Chinese manufacturers do not know, low reliability will lead to quick replacement time. than usual, causing downtime and affecting the production process.

2- Using the wrong pressure reducing valve: Using the wrong pressure reducing valve causes damage to the spring of the valve or installing a poor quality Y filter resulting in dust and sediment causing disc jam, causing disc warping leading to damaged.

To extend maintenance time, replace pressure reducing valve – pressure relief valve You should use famous pressure reducing valve such as Japanese Yoshitake pressure reducing valve with models GP-1000, GP-1000 EN HEN, GP-1001 GP -1001EN, GP-2000, pressure reducing valve GD-200H, YNV in Korea. In addition, it must be combined with quality Y Yoshitake SY-40 filter and water separator in front of pressure reducing valve to achieve high efficiency.

Please refer to the following diagram of the pressure reducing valve system: Pressure reducing valves in Vietnam