Since the 18th century, butterfly valves were used, which were also used by James Watt for steam engines at the time, which are now widely used for their advantages of being compact and cheaper than their counterparts. Others. other valve. Especially replacing ball valves in industries: oil, gas … There are many types of butterfly valves that can withstand temperatures up to 300 degrees Celsius and are used for the chemical industry.

A butterfly valve is an open and closed valve with the valve disc located at the center of the valve with a guide. Positioning bar connected to outside with handle open and close.

Principle of operation of the butterfly valve:

The butterfly valve operates with the principle of a closed valve disc. The valve disc opens and closes thanks to the external rotation of the handle via the connecting shaft between the control arm and the disc.

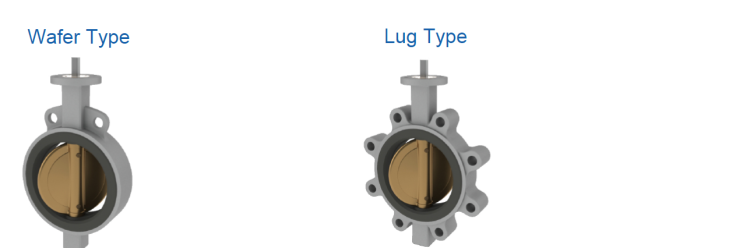

Butterfly valve classification: Butterfly valve is divided into 2 main types according to how it works

1- Lug type butterfly valve: This type uses multiple threaded holes (similar to 3-piece ball valves) that can be removed without affecting the other side. This is done by adding multiple threaded holes and two separate sets of screws on both sides of the flange.

2- Safety type butterfly valve: One type is used as check valve to prevent backflow of media